Spunlace Nonwoven Fabrics For Wet Wipe Material

For wet wipes manufacturer,spun-lace nonwoven fabrics is the most commonly used material in wet wipe production.We would like to discuss more details which can guide the wipe manufacturers to know well about spun-lace nonwoven and know how to choose the right spun-lace nonwoven for their production to boost their business.The content are shown as follows:

1. What is Spunlace nonwoven fabric?

2. Spunlace nonwoven fabric production process

3. Why spunlace nonwoven fabrics is the best material used in wet wipe production?

4. Fibers used in spunlace nonwoven fabrics for wet wipe production

5. Composition options of spunlace nonwoven for wet wipes

6. Pattern types of spunlace nonwoven for wet wipe material

7. Thickness options of spunlace nonwoven for wet wipe material

8. Basic requirements for spunlace nonwoven fabrics(specially for wet wipe material) production

9. Quality Inspection procedure for spunlace nonwoven fabrics rolls(specially for wet wipes)

1. What is Spunlace nonwoven fabric?

Spunlace nonwoven is a newly developed nonwoven material process,spunlace is also called Hydroentanglement.It was developed by Dupont and Chicopee in 1970s.In recent years,the performance of spunlace nonwoven fabrics is improved contiguously as spunlace process developing fast.Spunlace nonwoven process(also called water Jet process).In Spunlace process,high pressure water flow would jet onto the fiber web continuously,under the water power,the fibers in web would move and rearrange and bond each other.Thus the fiber web is strengthened to provide qualified physical and mechanical properties.That is how spunlace nonwoven come into being.

2. Spunlace nonwoven fabric production process

Fiber preparation:Feed the fibers and weight them accurately,deliver quantitative fibers to coarse opening machine and blending box.Fiber material is fine open through fine opening machine behind blending box.Then the conveyer deliver them to the storage box; When choosing fibers for spunlace nonwoven fabrics,we need to take cost,machinability and purpose of finished products.Both natural fibers and chemical fibers can be used in production of spunlace nonwoven fabrics.

Mixed carding and fiber web formation:The main role played by mixed carding to distribute the fibers evenly and form single fibers,then through further blending,impurity removal to form fiber net;The fibers after carding should have good quality to provide breathable and even spunlace nonwoven fabrics;fiber web formation is to make the fiber material to form loose structure;Fiber can be chosen based on the fiber web formation methods,thus fibers can be staple fiber or long fiber;There are dry laid web formation,wet laid web formation and polymer extrusion web formation methods.

Stretching and water jet strengthening:fiber web strengthening is carried out by certain process to strengthen the fibers within web.Thus the fiber web can be provided high strength.As a result,the fiber web after strengthening provides good mechanical properties and appearance.

Functional Finish:Functional finish of spunlace nonwoven fabrics help in improve performance,function and appearance;Through mechanical and chemical method,the nonwoven fabrics is formed and turn into products for use.For spun lace nonwoven fabrics,coating and laminating can be used for products finish process to improve serviceability and service life.

3.Why spunlace nonwoven fabrics is the best material used in wet wipe production?

Spunlace nonwoven fabrics manufacturing process makes use of water power to bond the fibers web.Its physical and mechanical properties fit wipe production needs.Its characteristics are shown as follows:

- No binder is used in the manufacturing process.Since it makes use of water power to strengthen the fiber web.No chemical binder is needed.This eco-friendly feature match against the needs of wipe application.

- No fibers come off during usage,it is ideal for cleaning.

- 3Fiber distribution within web is even,so it has excellent Longitudinal and transverse tension.It is not easy to tear during usage.

- It feels soft and would never cause scratch on the surface to be cleaned.

- 5.Super strong absorbing capacity for wet wipes.

- Good ventilation

4. Fibers used in spunlace nonwoven fabrics for wet wipe production

There are various fibers which can be used in spunlace nonwoven fabrics for wet wipes,generally,there are two types.

Natural plants fibers used in spunlace nonwoven fabrics for production of wet wipes:

Cotton fibers,wood pulp,bamboo fibers,lyocell fibers

Chemical fibers used in wet wipes:Viscose fibers,PET(polyester),PP(polypropylene),cellulose

5. Composition options of spunlace nonwoven for wet wipes

For different types of wet wipes,different material composition should be provided based on wipe types.

5.1 Cosmetic/Baby wipes composition options

5.1.1 Viscose+PET (polyester)

Generally,the ratio between Viscose and PET has different combinations:3:7,5:5,7:3

3:7 means that 30% are viscose and 70% are PET.The higher of viscose ratio means higher production cost.More viscose content means wipes are softer and higher absorbing capacity.Generally,5:5 ratio is a cost effective composition option.

5.1.2 Woodpulp+Cellulose

Woodpulp fibers have good cleaning property and absorbing capacity.Cellulose fiber comes from plants.The composition option offer biodegradable benefits for baby wipes.The addition of wood-pulp can reduce the cost of wipe production.

5.1.3 Pure cotton

For cosmetic/baby application,100% cotton material is high end option.Cotton fibers deliver high tensile strength,super soft skin touch and high absorbing capacity.Thus,pure cotton wipes provide great user experience.There is no doubt,the price is much higher than others.

5.2 Flushable/biodegradable wet wipe composition

Flushable/biodegradable wet wipes are becoming more and more popular because of their eco-friendly benefits.

5.2.1 For flushable wet wipes

Most common composition option is wood pulp+viscose.The option is the most common one in the market.With different ratio of wood pulp and viscose,they can be flushed down into the drain.

5.2.2 For biodegradable wet wipes

Bamboo,cotton,wood pulp.Neither PET nor PP can be use in biodegradable wet wipes since there are plastic fibers in it which is not biodegradable.

There are various composition options for spunlace nonwoven fabrics used for wet wipes.You can also create your own featured composition option.

6.Pattern types of spunlace nonwoven for wet wipe material

For spunlace nonwoven for wet wipe,generally,there are three types of pattern:Plain(parallel lapping),Embossed,mesh(cross lapping).

They have different appearances and the cost is different.Plain type is the cheaper than other two.However,plain structure has less tensile strength than mesh type.However,plain pattern is strong enough for general purpose wipe used for body cleaning.While,for wiping cloth,cross lapping pattern spunlace is better since it is not easy to tear.

7.Thickness options of spunlace nonwoven for wet wipe material

Thickness:the thickness of nonwoven fabrics is measured by g/m2,that means the weight in each square meter.For instance,50gsm means the material weight is 50gram per square meter.The higher number means thicker material.There is no doubt that thicker material is better than thinner one,but the cost is also higher.For spunlace nonwoven fabrics for wet wipe production,40-60gsm is ideal for daily use.More than this number is not recommended since the cost is higher and the consumers can not feel much difference in thickness.

8.Basic requirements for spunlace nonwoven fabrics(specially for wet wipe material) production

8.1.1 The manufacturer should have the ability to design customized material specification and technology parameters based on different purpose of wet wipes,and Eco friendly fiber material should be preference.

8.1.2 All the raw material should comply the requirement of baby products.

8.1.3 Workshop should be provided with environment condition control capacity including temperature control,moisture control and cleanness control.

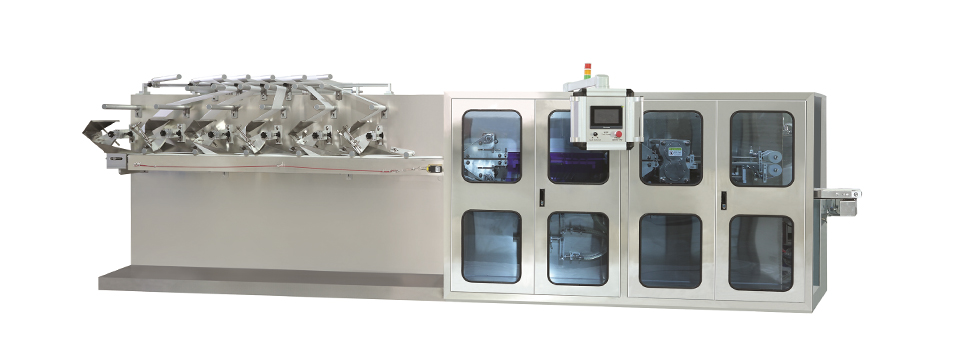

8.1.4 To ensure the quality of products,a series of equipment should be equipped during the production process: On-Line Inspection Of Surface Defect,On-line digital weight measurement,On-line monitor of moisture content, metal detector,auto-tensiometer (for material cutting).

8.1.5 Application of computer controlled automatic production line and fully automatic high efficiency water circulation system during production.Clean energy is used for overall production.

8.1.6 Manufacturer should be equipped with microbiology laboratory,automatic electronic strength tester,bake oven,electronic balance,thickness gauge,buckling length tester,PH tester,standard light box etc.

9.2 Quality inspection rule

For quality inspection,the inspection result should be based on batch from same one supplier.

If for one batch of spunlace nonwoven fabrics,the items including breaking strength,breaking hygienic index,absorption capacity,thickness etc are found unqualified,thus this batch of products are considered as unqualified.