Wet towel machine production lines typically incorporate several safety features to ensure the protection of operators and maintain a safe working environment.

Some common safety features include:

- Emergency stop button: This button allows operators to quickly halt the machine’s operation in case of an emergency or unsafe condition.

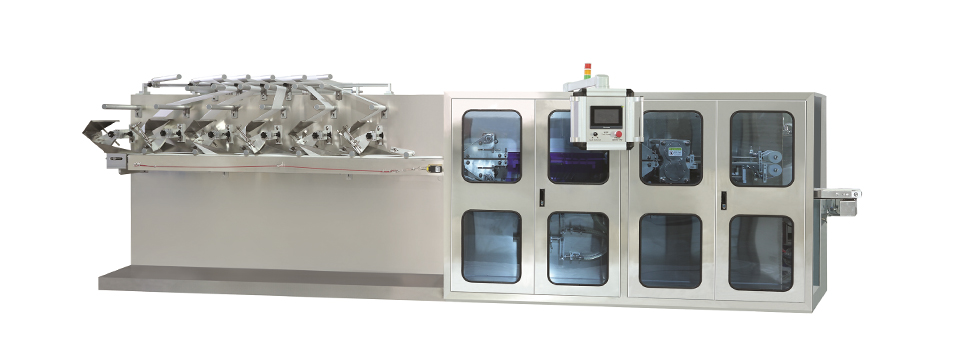

- Safety guards: Physical barriers or guards are installed around moving parts and potentially hazardous areas of the machine to prevent accidental contact and injuries.

- Safety sensors: Proximity sensors or other types of sensors are used to detect the presence of objects or hands in hazardous areas, triggering automatic shutdown or activation of safety measures.

- Overload protection: Systems are implemented to prevent the machine from operating beyond its specified capacity, reducing the risk of equipment damage and operator injury.

- Interlocking systems: Interlocks ensure that certain actions or conditions must be met before the machine can operate, such as closing protective covers or securing access doors.

- Safety signage and labeling: Clear signage and labeling are placed on the machine to indicate potential hazards, operating instructions, and safety precautions.

- Training and education: Operators receive comprehensive training on safe operating procedures, wet towel machine production line including handling of equipment, emergency protocols, and proper use of safety features.

- Regular maintenance and inspections: Scheduled maintenance and inspections are conducted to identify and address potential safety hazards, such as worn parts or malfunctioning safety devices.

- Compliance with regulations: Wet towel machine production lines are designed and manufactured in accordance with relevant safety standards and regulations to ensure compliance and adherence to safety guidelines.

By incorporating these safety features and practices, wet towel machine production lines can minimize the risk of accidents, injuries, and equipment damage, creating a safer and more productive working environment for operators.